Reto explains: How a watch is made

The dial – the face of the watch

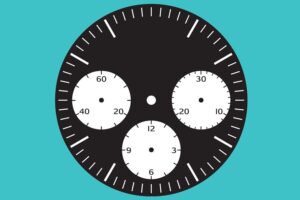

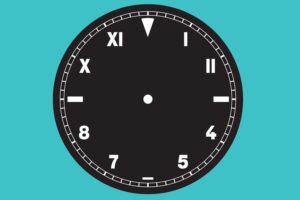

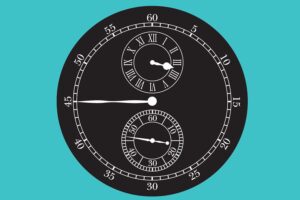

The dial is the face of the watch in two ways. Firstly, the dial is what you see when you look at a watch for the first time. It decides whether you like the watch or not. Secondly, the functions of the watch are visible on this “face”; the display of the time, the date, the moon phase, the second time zone, etc.

What is a dial made of? In most cases, a blank is made of brass. This blank is then either lacquered, galvanised or covered with a coating such as mother-of-pearl. Other materials used to make dials are nickel silver, bronze, copper, gold, silver or platinum. New materials such as carbon, stone, wood or sapphire glass are also used for dials.

Often, the surface of the dial is also specially treated. This can be done by a special cut (Geneva stripes, sunburst, etc.) or by a guillochage.

Once the dial has been lacquered and decorated, the markings are applied. This is done either by pad printing based on a previously produced cliché and/or by applying appliques. The appliques can be made of different materials and the pad printing is done with normal or fluorescent ink.

How is a dial created? The first step is to decide which movement and which case we want to work with. While the movement defines the functionality to be depicted on the dial, the case determines the possible height on the one hand and the visible diameter of the dial, the so-called overture, on the other.

In a next step, we sit down with our designer, Etienne Ruffieux, and first define the basic type of dial (see separate box for explanations). Then the design criteria are determined together:

- What effect/feeling/expression (or in English “mood”) should the dial convey?

- Which functions should be emphasised?

- How will the DNA of RB Baumgartner be implemented?

- In which colours and surface designs should the dial be produced?

- How will the markings on the dial be made (print, appliqués)?

Once the basic type has been determined and the questions answered, the first draft is created by the designer. This is jointly checked and, if necessary, adjusted, and then the production plan is drawn up, which, in addition to the design, contains all the necessary technical details such as size, thickness, position of the dial feet, etc. The first draft is then sent to the production department for approval.

With this plan, the dial manufacturer (Cadranier) creates the prototypes. These are checked by us with regard to design, effect and compliance with the technical specifications and a prototype of the entire watch is created. Once all open points have been settled, the production of the dials is commissioned. The production time is usually 4 – 6 months.

Overview of the dial base types

SIMILAR ARTICLES

Watch care – 3 simple tips to make your watch last a lifetime

BASCULE: A unique combination of tradition and craftsmanship